Letterpress

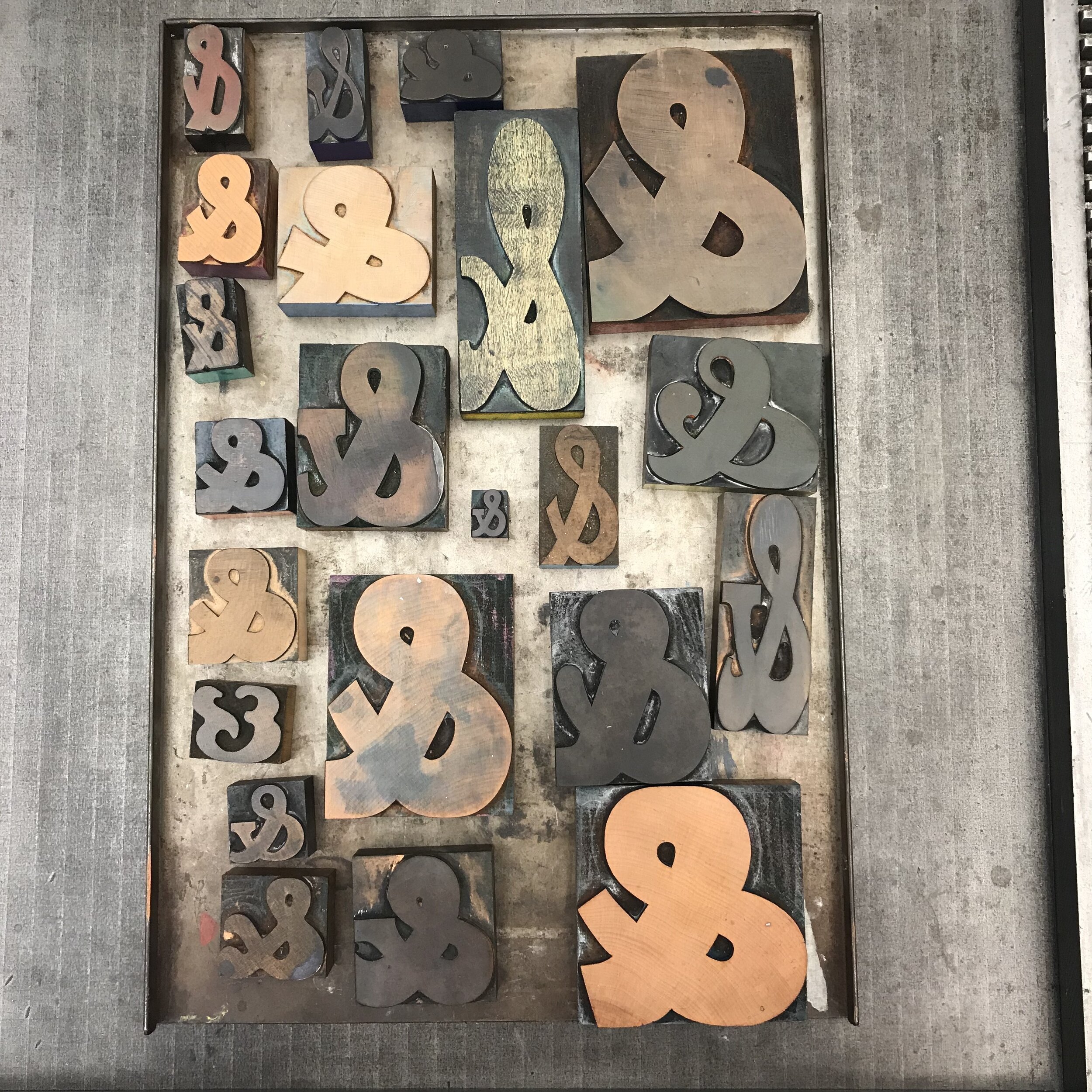

Letterpress is a relief printing process that involves a printing press and an inked raised surface. A printer uses a composing stick to arrange moveable type, made of metal or wood, and then locks the setup into a chase or onto the press bed to be registered, inked, and printed.

Letterpress can include other forms of relief printing, such as woodcuts, linocuts, or photo-etched zinc plates, all of which can be printed alongside metal and wood type. There are also plastic plates that commercial print studios use today called Photopolymer plates. Polymer plate development is a modern Letterpress technique that involves a light sensitive plastic plate that can be exposed using a negative film. Once a raised plate is developed it can then be mounted to a metal base making it “type high” for commercial printing.

Letterpress Equipment

Vandercook Universal I Printing Press W/Adjustable Bed (22” x 15.5” bed size)

Vandercook Universal I Printing Press (22” x 15.5” bed size)

Vandercook Universal I Printing Press (22” x 15.5” bed size)

Vandercook No. 2 Proof Press (22.5” x 20” bed size)

Chandler & Price 8 x 12 Old Style Platen Press (12” x 8” bed size)

American Table Top Platen Press (12” x 8” bed size)

R. Hoe Gravity Proof Press (24” x 16” bed size)

Hammond Glider (Trim-O-Saw) Type Saw

Challenge Machinery Guillotine Paper Cutter (25” x 23” max. paper size)

Dahle 569 Paper Cutters (27″ x 22″)

3 Hamilton Metal Type Cabinets

4 Hamilton Wood Type Cabinets

AZ PA 520 Inox Letterpress Photo-Polymer Platemaker (18” x 13” max. plate size)