Silkscreen

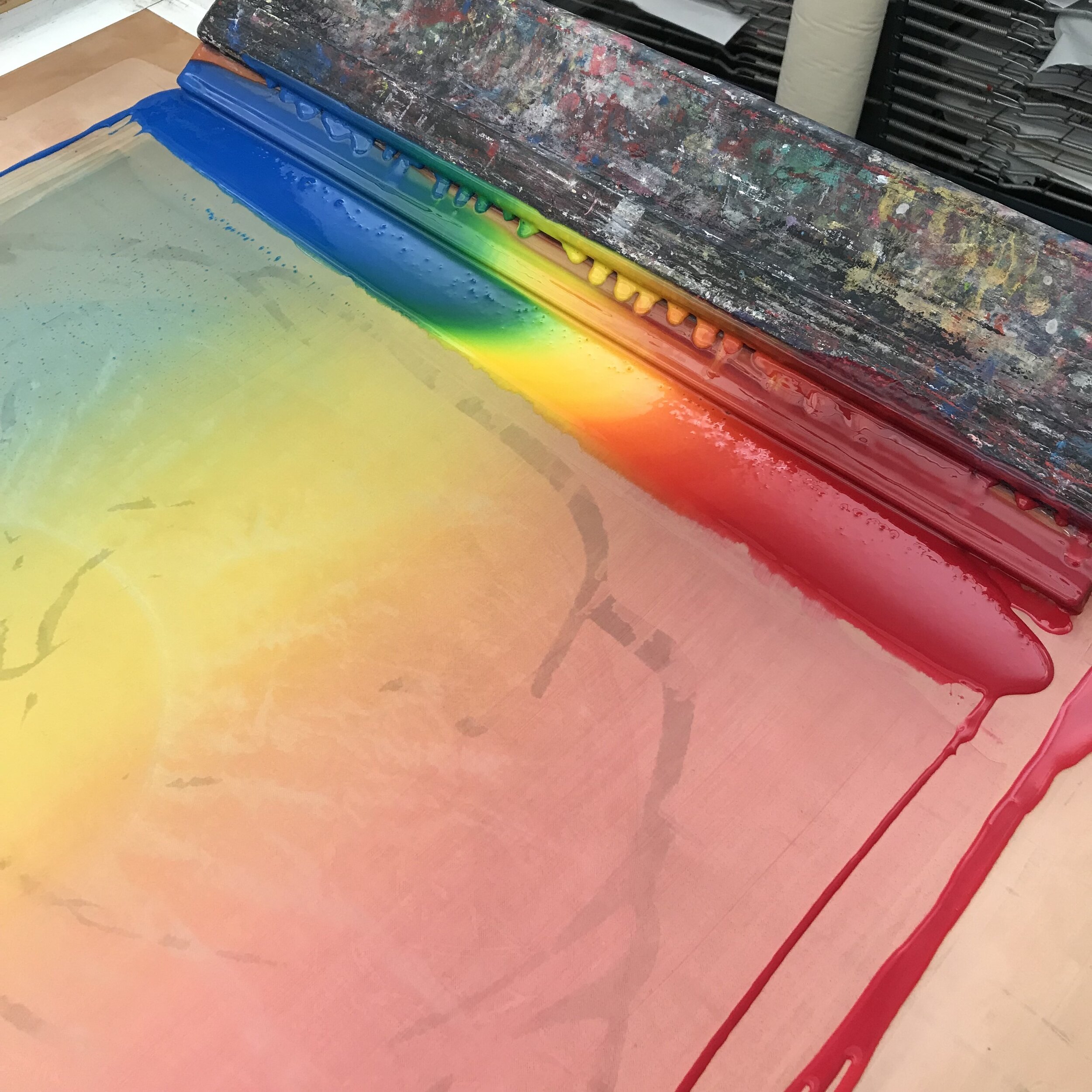

Silkscreen, Screen Printing, or Serigraphy, is a printing technique where a stencil and a framed mesh screen are used to transfer ink onto a flat substrate to create an image. Stencils are either designed digitally or are drawn by hand onto a transparency and are transferred onto the screen using a photographic process involving a light-sensitive emulsion and exposure to UV light. Once applied to the screen the stencil blocks off areas and leaves other areas open for ink to pass through. The screen is hinged to a table where a rubber blade called a “squeegee” is pulled up across the screen to fill or “flood” the open areas of the screen with ink. A reverse downward pull with pressure causes the screen to touch the surface of the substrate, with this motion ink is forced through the open areas of the screen and is deposited onto the substrate along the

squeegee’s line of contact.

Only one color can be printed at a time. For multicolored compositions, several screens must be made in order to layer colors. To create multiples or an “edition” of a print, each color layer must be aligned or “registered” in the same place and printed in the same order to ensure that each print resembles the original image or artwork.

Silkscreen Equipment

2 NuArc Tri-Light UV Exposure Units (60” x 42”)

4 Silkscreen Drying Racks (52” x 40”)

1 Four-Color Rotary Printer

4 Large Silkscreen Wash-up Sinks

2 Hydro-Tek Pressure Washers

2 Dahle 569 Paper Cutters (27″ x 22″)

Silkscreen Squeegees

Emulsion Scoop Coaters (various sizes)

TW Graphics Silkscreen Inks

Permaset Modifiers

Jacquard Textile Inks

Holdens Photo-Emulsion and Reclaimer

2 Eyewash Stations